Chemical Colour Imaging

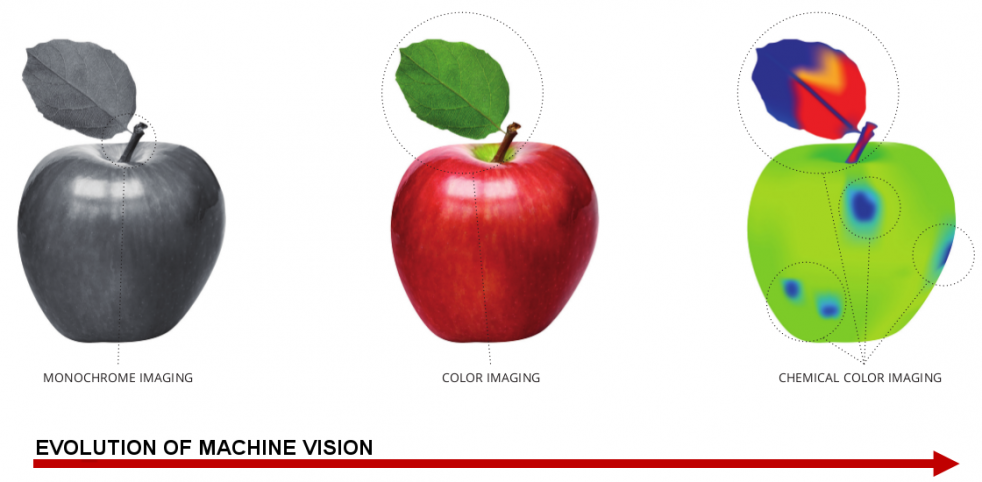

Chemical Colour Imaging (CCI) represents a new processing technology, which combines essential advantages of the basic technologies of chemical imaging (hyperspectral imaging) and colour imaging (Colour image processing) and makes chemical material properties accessible to a completely new range of users through new approaches to data processing.

Dramatic simplifications in handling, as well as the opportunity for real-time processing of highly complex camera data, are the keys to an extensive industrial use of this chemical camera technology. The abstraction of highly complex spectral information through chemical features makes handling of the cameras on a deep level accessible to the user and interpretable, even without a profound knowledge of the basic technologies. New aspects of dealing with chemical information arise and these accelerate continuous further development of Chemical Colour Imaging.

Chemical Colour Imaging aims at a holistic approach considering the advantages of spectroscopic and image processing techniques. Hyperspectral cube data are described by colour images holding spatial information together with spectroscopic information coded by colour. Such a data format allows the perception of targeted information in a high-dimensional data set (like a cube) as well as the co-processing by means of (colour) image processing methodology. As a consequence, the validation of gained perceptions can be realized by a manually or automated comparison with expectations. This circumstance simplifies the process of configuring of hyperspectral data processing (to point out specific spectroscopic information) enormously.

Chemical Colour Imaging is applied typically by solution providers, like instrument builders, for industrial purposes. Its main markets today are recycling, food, mining and also the pharmaceutical industry. By adapting a hyperspectral camera with a real-time processing core, Chemical Colour Imaging turns the camera system to an easy-to-understand and intuitive configurable “chemical colour camera”. Since the output data is in a standardized machine vision format, all available image processing solutions can be facilitated for tasks like decision generation, counting or monitoring based on chemical information.

The methods of Chemical Colour Imaging provide unique possibilities:

- Configuration data sets for camera systems by applying highly abstracted and plain statistical methods

- Simple and intuitive handling of hyperspectral data

- Novel classifications of chemical and molecular information by using image processing methods

- Interpretation and processing of chemical and physical properties as relative information (expressed by colours)

- Ratings of distributions of chemical and physical information by using image processing methods.

Proof of Concept

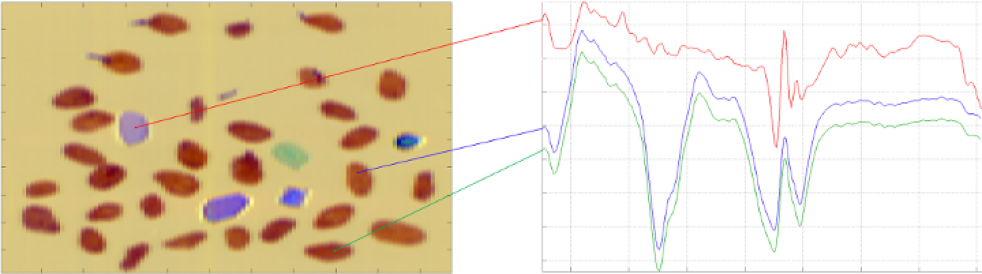

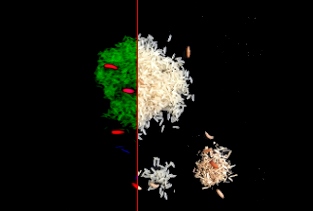

TheChemical Colour Image on the left shows raisins with impurities in between (paper, plastic). The blue and green arrows point two spectral positions of raisins. In the graph on the right it can be seen that points with similar colour also have similar spectra behind. The red arrow points a different colour. Consequently the spectrum (paper) is also different from the raisin spectra.

Bridging of Hyperspectral Imaging and Image Processing

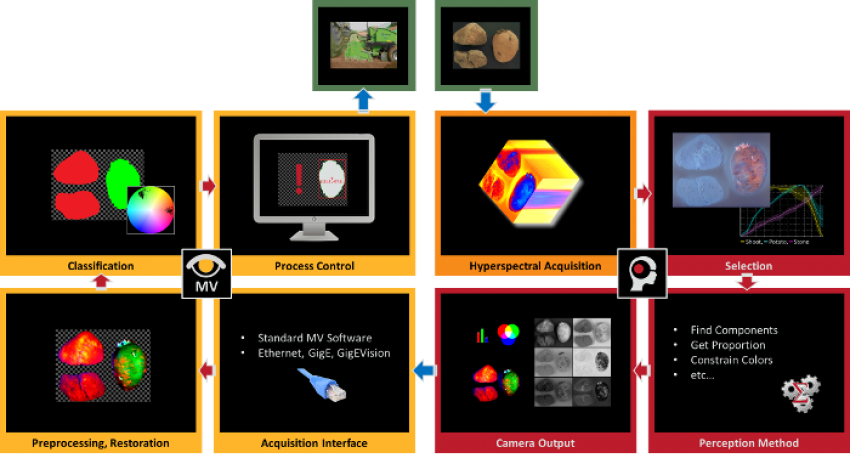

The figure above shows the process of an inline Chemical Colour Imaging solution. In the first step an unsupervised colour preview of a hyperspectral data cube is generated. Along this preview spectra or spectra sets of the objects can be selected and analyzed. By the intuitive use of predefined chemical property extraction modules, spectral features can be evaluated and defined. A Chemical Colour model is generated automatically by selecting relevant property scores (resulting from defined features) for the RGB-channels.

The generated RGB-image is then transformed to the HSV colour space which opens easy possibilities for a colour classification. Additional to the chemical object classification, more object properties can be collected and a final decision for the object can be made. By combining the advantages of hyperspectral imaging with the advantages of industrial image processing, new innovative machine vision solutions can be developed.

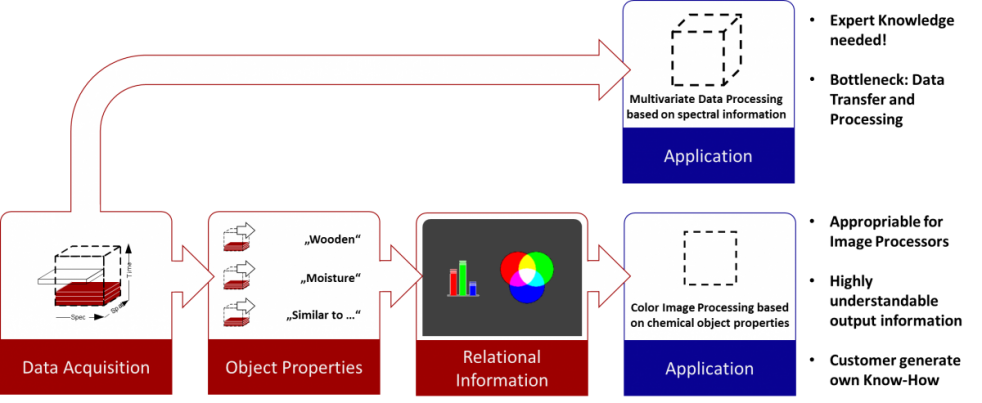

Chemical Colour Imaging compared to Hyperspectral Imaging

To develop applications based on hyperspectral cameras it was usually necessary to seek advice from experts of chemometry and spectroscopy. - Till now! By Chemical Colour Imaging hyperspectral cameras are integrated into existing image processing systems. By intuitive configuration options, chemical properties are extracted using established chemometric methods. By combining three properties, a colour impression (representing chemical relations information) is generated which is simple to understand and can be processed by image processing methods.

The resulting Chemical Colour Image of a scene shows object properties in Chemical Colours which do not represent the physical property colour. Instead objects with similar molecular structure are represented by similar colours; different objects by different colours.

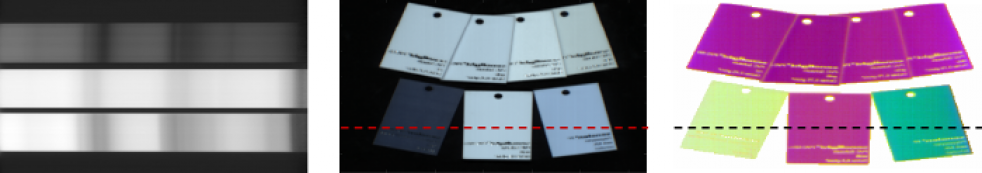

Center: CCI-preview of different plastics; right: Chemical Colour Image of different plastics. The Chemical Colours correlate with the molecular structure of the samples. The dashed line marks the moment of record shown in the left handed image; Left: Hyperspectral image at a specific moment. Spectral information is shown horizontally and spatial information is shown vertically.

- The Perception System transforms sensor raw signals into corrected, standardised hyperspectral cube data allowing the intermediate operation of your hyperspectral system.